TIFCO Industries Specialty Products

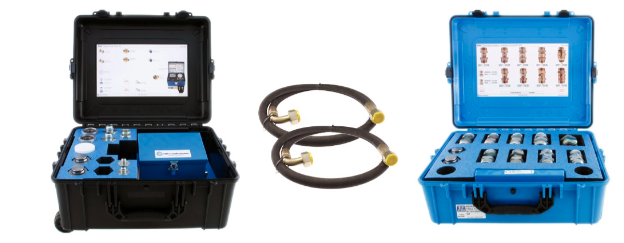

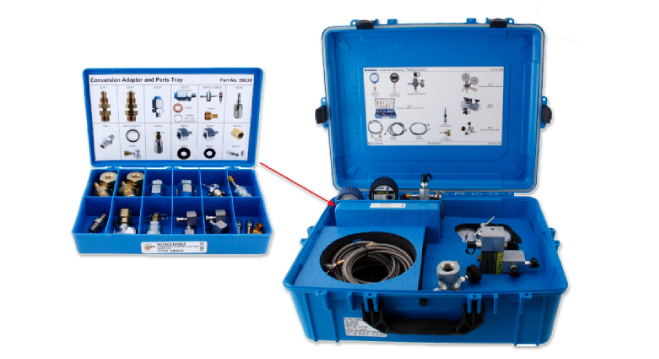

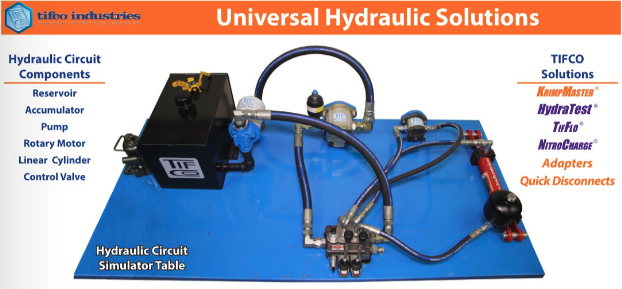

• HydraTest ® is a unique System that has universal application and is therefore capable of testing the pressure on all brands of Mobile Hydraulic Equipment in a single kit that includes 210 components.

This means no matter where you are or what you are required to maintain, diagnose, or pressure test Technicians have the test tools available to keep equipment operating. All this while saving valuable space on your service vehicles and the cost of purchasing and maintaining several OEM or single brand/style test kits.

· Made in the USA

· Connects to smartphones and tablets via Bluetooth®

· Download the app for iOS or Android devices to display results on a smart phone or tablet

· Tests pressure from 0 to 10,000 psi, with 0.25% ultra high accuracy

· 24–36 month battery life (replacement proprietary battery Part No. 79829)

· 2 times over pressure standard

· Wetted parts are one piece, 17-4 SS (no internal O-rings or welds)

· Operating temperature range from -40° to 185°F

· Stainless steel and high-impact polycarbonate construction

· Compatible with all brands of mobile heavy equipment

Specifications

Pressure Range: 0 to 10,000 psi

Accuracy: 0.25% of 10,000 psi

Overrange Protection: Up to 20,000 psi

Burst Pressure: 20,000 psi

Pressure Cycles: >100 million

Update Time: ≤ 1 msec

Connection Distance: 250 feet (line of sight)

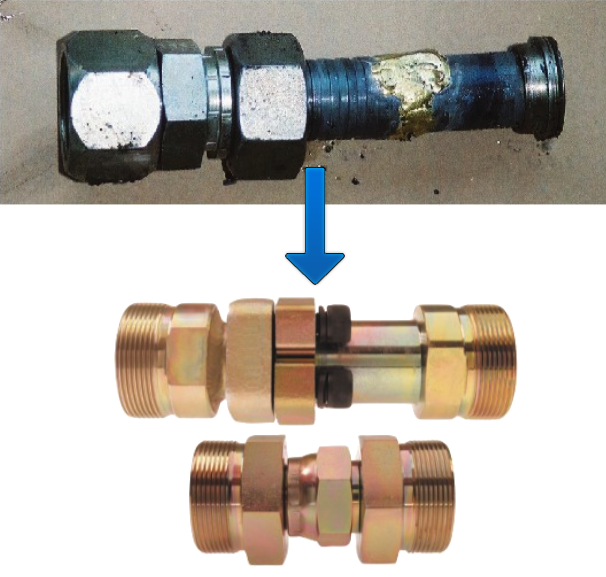

• The problem of using field made-up welded or brazed unsafe and untested connections is solved with Tifflo ® Conversion Adapting Test Tools to connect to hose ends on equipment.

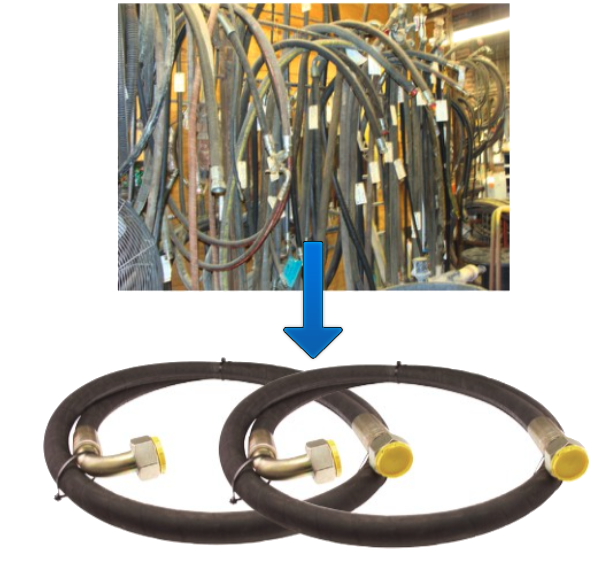

• Solve the expensive problem of several stored hoses with different hose ends crimped on by using Tifflo ® Hoses that have common UTT threads to match both Tifflo ® Conversion Adapting Test Tools and Flow Meter Inlet and Outlet Adapters.

• TifFlo ® has the same unique qualities as HydraTest ® in that it solves problems that Technicians experience. Connecting Tifflo's ® Conversion Adapting Test Tools onto existing hose end fittings coming from the pump to a control valve allows the Technician to connect the flow meter into the circuit so that a flow test can be made. These Test Tools solve the problem of making up connections in the field using uncommon parts. Using untested made-up fittings is not only a liability issue, but more importantly a safety issue.

The NitroCharge ® System, just like HydraTest ® and TifFlo ®, utilizes common styles and thread patterns to connect accumulators to nitrogen bottles for the purpose of checking pressure, charging, or discharging accumulators. The problem encountered by Technicians is that different accumulators have different charging port styles and thread patterns which create the necessity to have different connecting fittings to service the accumulator.

This problem is solved by using NitroCharge ® conversion adapting test tools to install onto your existing accumulators. These conversion adapting test tools are then connected to a common hose end connection that can then be connected to either a dual or single manifold or directly to a nitrogen bottle for charging or discharging.

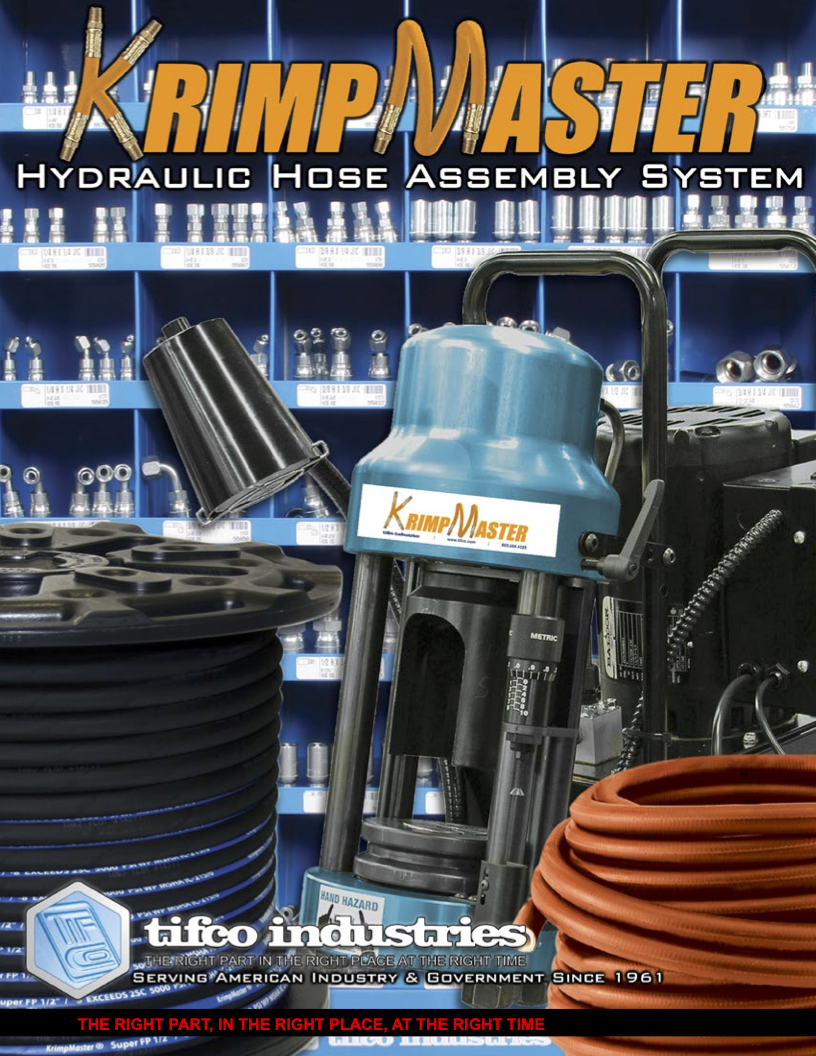

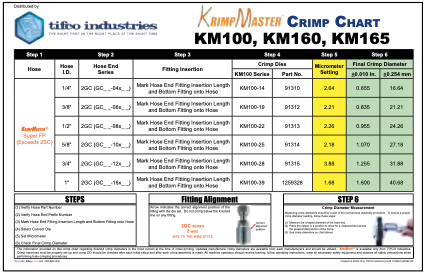

• Krimpmaster ® is a unique hydraulic hose assembly system that allows Krimpmaster ® products to work as a matched system or with other OEM machines, hose and fittings for emergency service repairs. This cross-compatibility means that it is possible to make emergency service repairs using Krimpmaster ® products from multiple manufacturers.

• Your TIFCO Inventory Maintenance Specialist will provide you with custom, laminated Crimp Charts showing step-by-step hose assembly procedures so that each final crimp diameter can be accurately verified. Your TIFCO Inventory Maintenance Specialist will also be able to help with training, product and technical questions and will always ensure that you have The Right Part, In the Right Place at the Right Time.

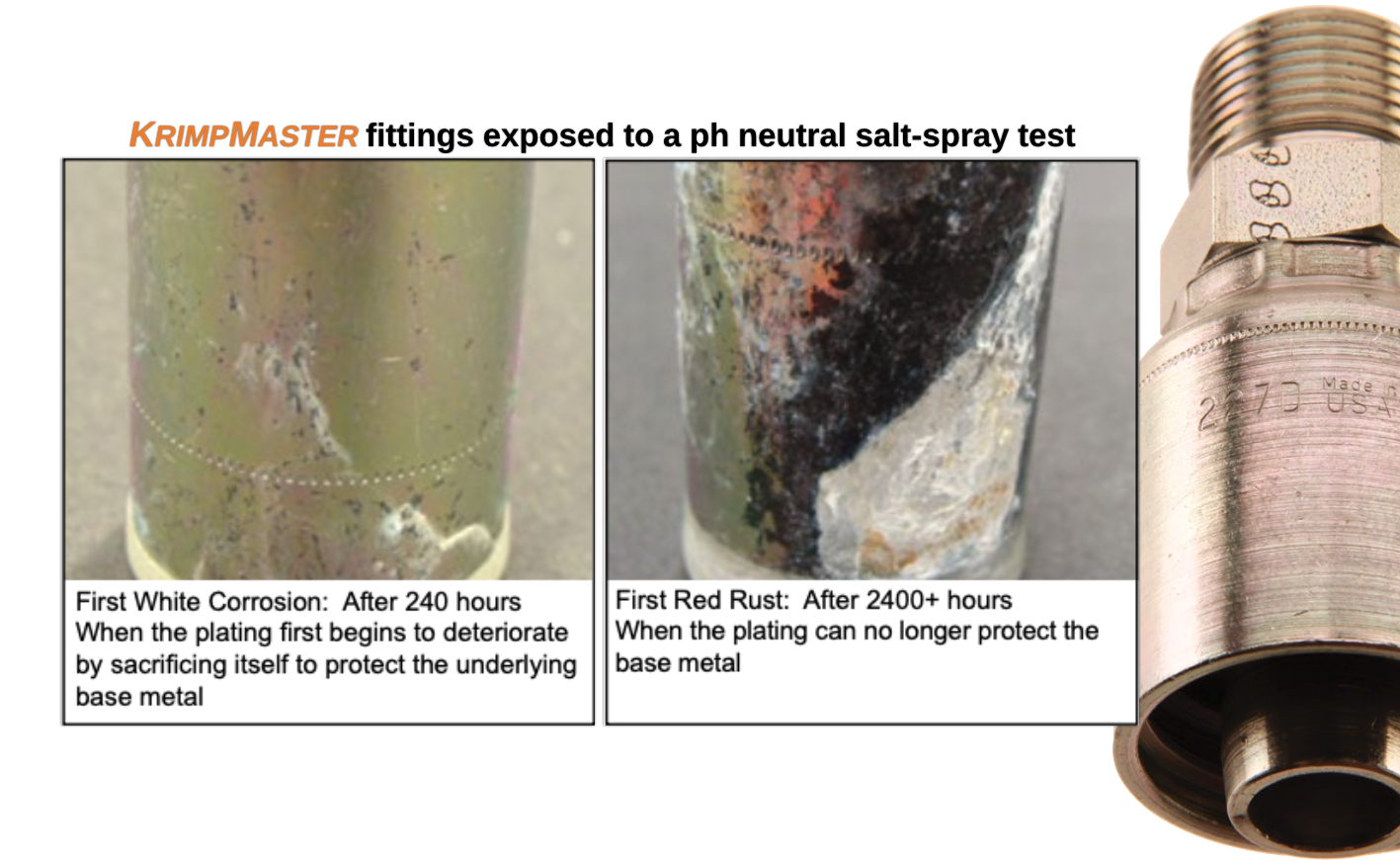

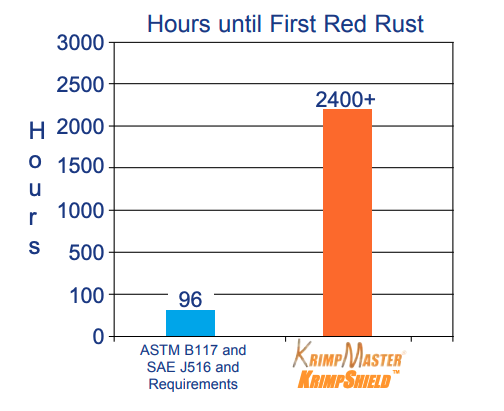

• TIFCO Industries is proud to announce a new plating technology: Krimpshield® a new, extremely corrosion resistant plating available exclusively on TIFCO's line of Krimpmaster® Hose Ends.

• Up to 240 hours before white corrosion and 2400+ hours before red rust • Environmentally friendly

• No hazardous hexavalent chromium

• ROHS compliant

• Made in the USA

This process and plating is environmentally friendly and provides rust and corrosion protection above and beyond current specifications. When tested under SAE J516 and ASTM B117 salt-spray conditions, it provides a minimum corrosion resistance of 300 salt-spray hours until first white corrosion and 600 hours until first red rust.

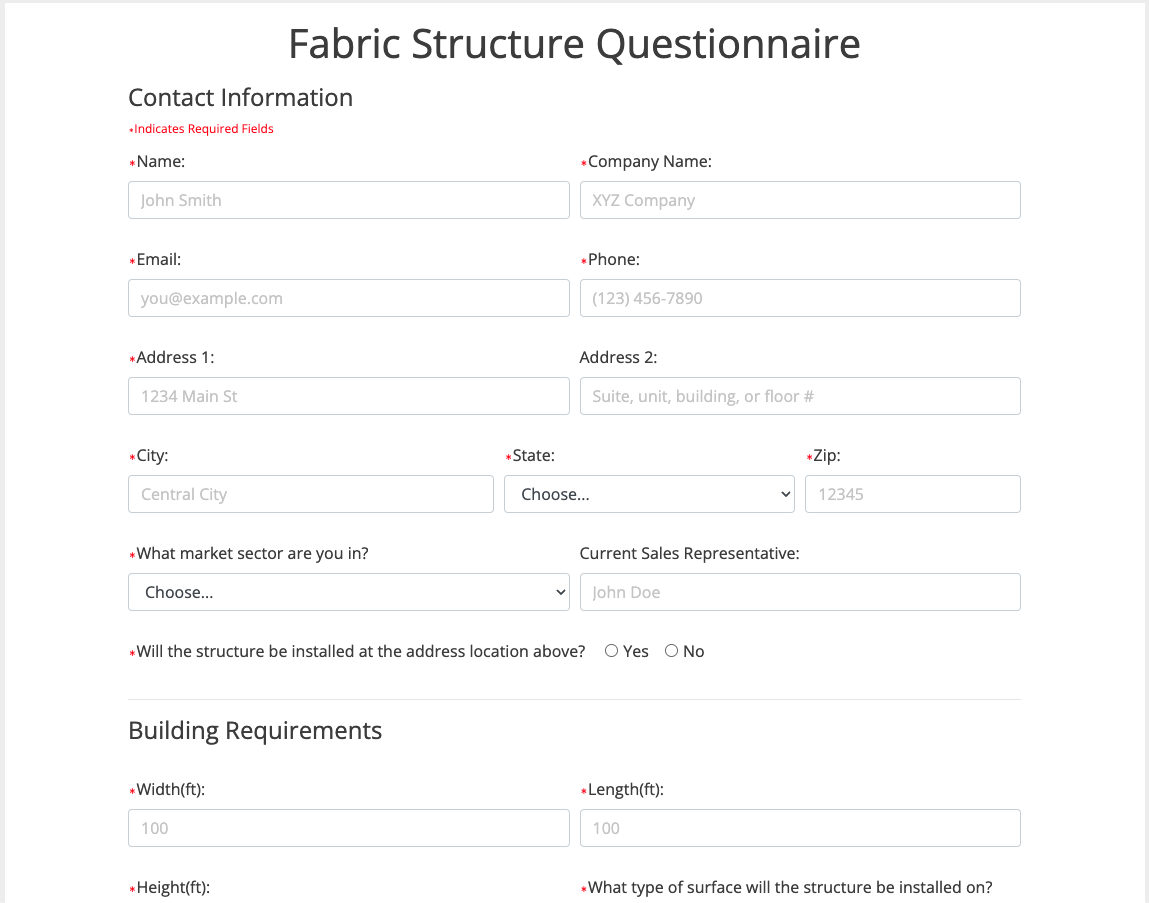

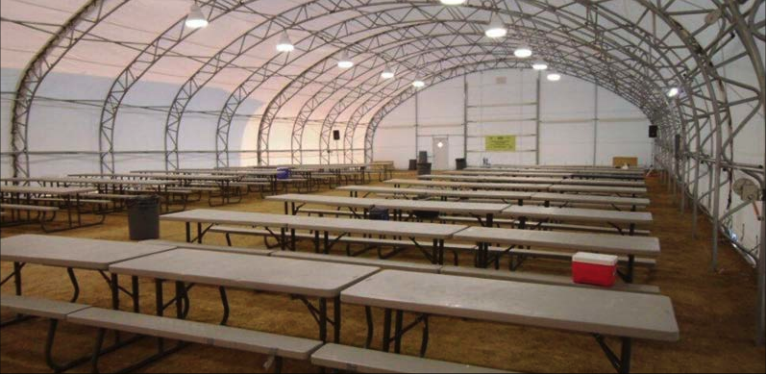

Fabric Shelters

Enclosed or Drive-Through fabric shelter structures that can be rapidly constructed on location, customizable for your exact needs. Constructed with a rugged steel frame with a strong, durable tensioned fabric covering. 100% American Made.

Using a 82081 CGA-580 bottle

adapter connect

the 82075 regulator to the nitrogen bottle.

Using a 82081 CGA-580 bottle

adapter connect

the 82075 regulator to the nitrogen bottle.

Connect an 82004 test hose

to the 82075

regulator.

Connect an 82004 test hose

to the 82075

regulator.

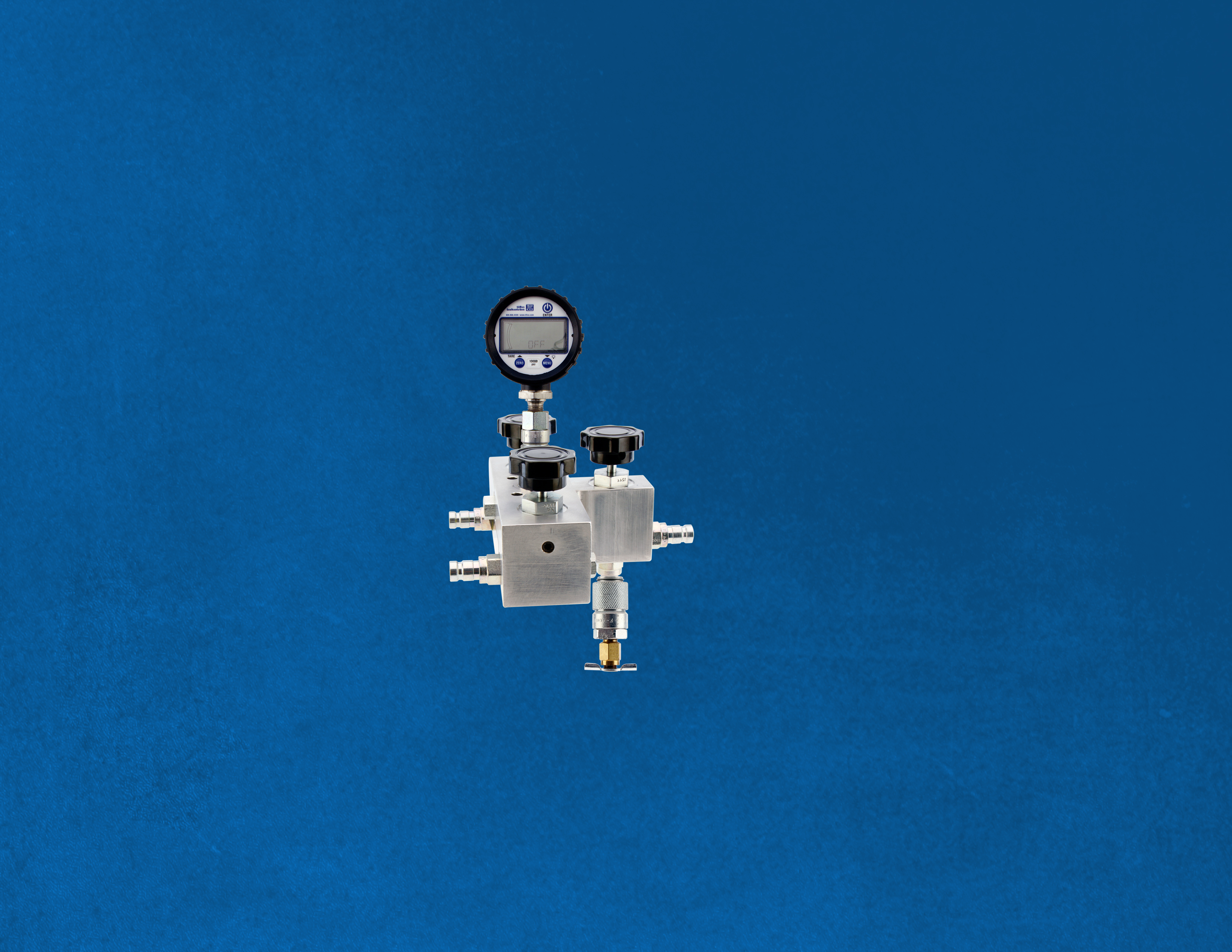

Connect the 79527 digital

gauge and 82088

bleed adapter to the 82000 dual manifold.

Connect the 79527 digital

gauge and 82088

bleed adapter to the 82000 dual manifold.

Connect the snap on

connection from the

82004 test hose to the inlet side of the 82000

dual manifold.

Connect the snap on

connection from the

82004 test hose to the inlet side of the 82000

dual manifold.

Connect the snap on

connection from the

82003 test hose to the outlet side of the 82000

dual manifold. Connect the proper Conversion

Adapting Test Tool to the accumulator and

connect the conversion adapter end of the

82003 to the Conversion Adapting Test Tool on

the accumulator.

Connect the snap on

connection from the

82003 test hose to the outlet side of the 82000

dual manifold. Connect the proper Conversion

Adapting Test Tool to the accumulator and

connect the conversion adapter end of the

82003 to the Conversion Adapting Test Tool on

the accumulator.

Dual Manifold available in

NitroCharge ® Kit No. 79626

Dual Manifold available in

NitroCharge ® Kit No. 79626

Using a 82081 CGA-580 bottle adapter connect the 82075

regulator to the nitrogen bottle.

Using a 82081 CGA-580 bottle adapter connect the 82075

regulator to the nitrogen bottle.

Connect a 82005 test hose to the 82075

regulator.

Connect a 82005 test hose to the 82075

regulator.

CConnect the conversion adapter end of the

82005 to the inlet side of the 82062 single

manifold.

CConnect the conversion adapter end of the

82005 to the inlet side of the 82062 single

manifold.

Connect the 79527 digital gauge to the 82062

single manifold. (Use 49013 analog gauge for

79627 starter kit)

Connect the 79527 digital gauge to the 82062

single manifold. (Use 49013 analog gauge for

79627 starter kit)

Connect the proper Conversion Adapting

Test Tool to the accumulator. Connect the

conversion adapter end of the 82062 single

manifold to the Conversion Adapting Test Tool

on the accumulator.

Connect the proper Conversion Adapting

Test Tool to the accumulator. Connect the

conversion adapter end of the 82062 single

manifold to the Conversion Adapting Test Tool

on the accumulator.

Single Manifold available in NitroCharge ® Kit No. 79626

and 79627

Single Manifold available in NitroCharge ® Kit No. 79626

and 79627